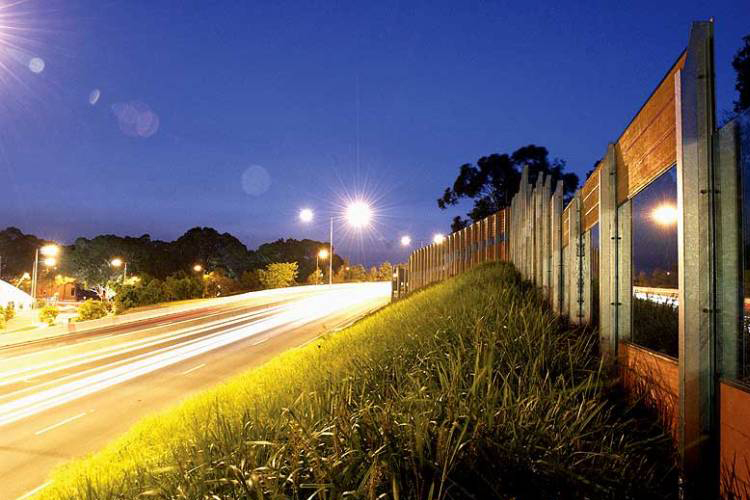

Winning the 2023 Australian Construction Achievement Award is a welcome achievement for CPB Contractors and our M80 Upgrade project team.

Delivery excellence, innovative thinking and clever solutions have been central to CPB Contractors’ success in our more than 90 year history, and this award is further recognition of our people’s expertise in sustainable construction to benefit industry, our clients and the communities where we work.

By working collaboratively with Major Road Projects Victoria, CPB Contractors and the M80 Upgrade team achieved best-for-project and community outcomes. Our people identified clever technical solutions that created environmental benefits while also enabling completion of the project six months ahead of the contractual date, opening more than a year ahead of schedule and under budget.

Importantly, commitment during the tender phase by both CPB Contractors and our client ensured the M80 Upgrade would be a leading example in diversity and inclusion for the civil construction sector, achieving a 40% female senior leadership team, 30% project staff were women and 3.1% Indigenous employee participation.

Thank you to both the Australian Construction Association and Engineers Australia for supporting the industry by encouraging best practice project delivery.

Michael Kalinowski

Executive General Manager – Vic, Tas & NZ

CPB Contractors